We can do it all

Wirefab, Inc. is an industry leader specializing in scalable manufacturing, engineered design, customizable fabrication, and efficient supply solutions. Rated one of the top wire forming companies in Worcester, MA, we operate 300+ machines across 85,000 square feet of facilities. We provide all of our services under one roof, giving you the benefit of one-stop shopping.

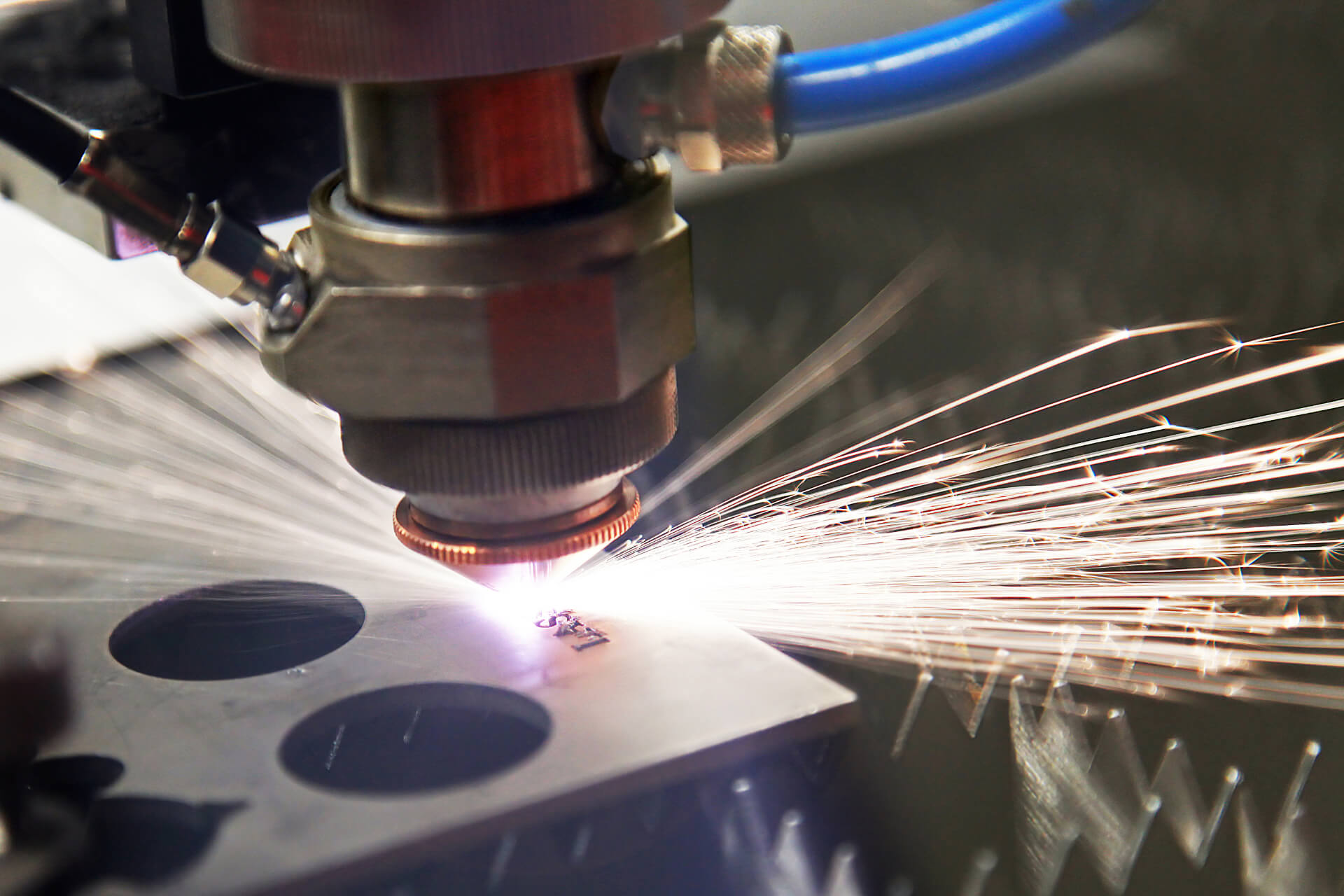

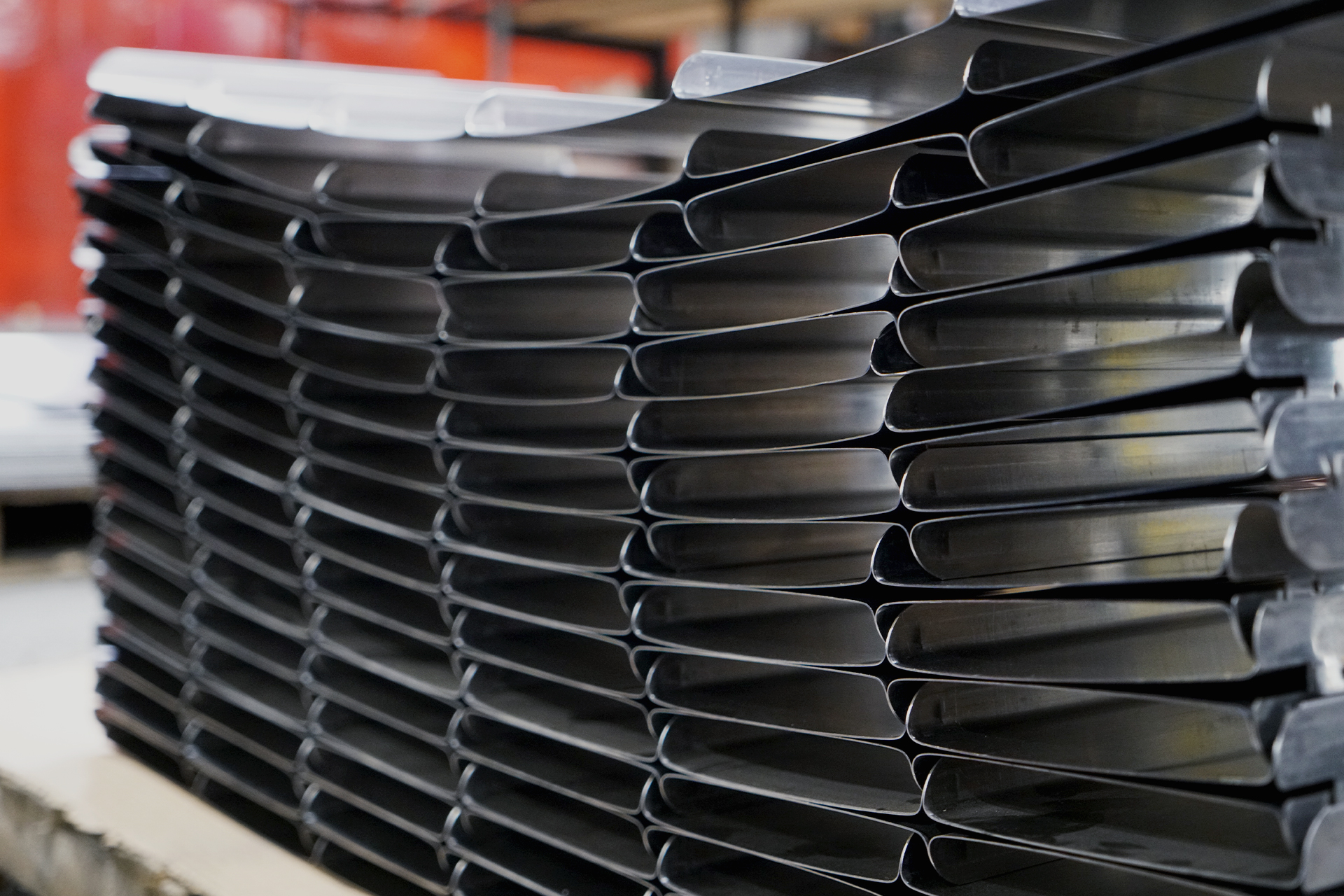

We specialize in bending, cutting, drilling, and forming tubes in a variety of finishes.

Our state-of-the-art CNC machines precisely drill, mill, chamfer, tap, turn, and bore.